DEPRO Have Just Introduced a New Compact ROV Concept, BLUEROC

We wanted to get a better understanding about the company behind this technology and contacted Depro AS and their Chief Marketing Officer Kenneth Olsen to get better insight. Depro AS delivers multidisciplinary products and technologies to meet companies needs for remote operated tool solutions and concepts. We learn more below.

OGI: Please tell us who Depro are and the history behind the company?

Olsen: Depro was founded in 2005, originating from Bryne Mekaniske. The team who started the company set increased focus on smart engineering and smart fabrication of subsea tooling.

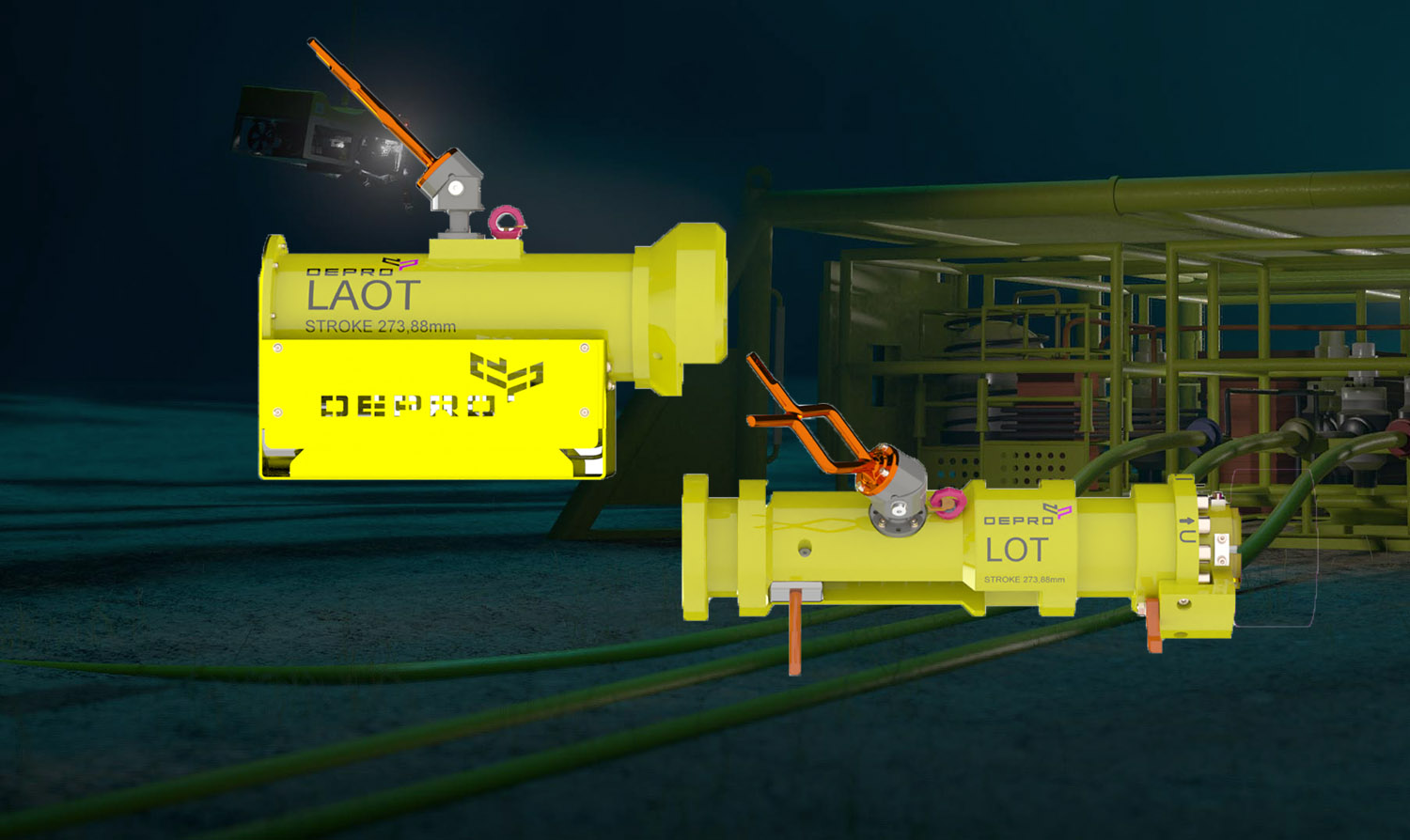

Today we have a modern new and effective office and workshop where we have multidiscipline competence and supplying products consisting of mechanical, hydraulic, and electrical technology. Depro is supplying all type of tooling and some permanent equipment for subsea use to the oil and gas industry. We have 46 employees and have a strong supplier network of whom we work closely with, with high capacity and world class competence. This gives us the opportunity to be attractive supplier to the global market and customers.

OGI: Could you tell me what Depro do and deliver, and how you serve the market?

Olsen: Our most important objective is to help our customers by fully understand what they need and what we can provide to meet their expectations. Depro have, from day one, been able to serve the customers quickly with reliable and attractive solutions. Most of our deliveries are connected to IMR subsea operations and ROV tooling.

Around 8 years ago, we started to develop more advanced tooling containing electrical control systems and fully electrically powered TMS system for work class ROV.

As a continuation of this development the idea and concept BLUEROC was created.

OGI: How does Depro see the future of the oil and gas business?

Olsen: I think it is important for the oil and gas industry to understand the changes within the energy sector and the challenge we have in front of us with reduced demand for oil and gas. There will be need for oil and gas products for the rest of this century, but at a point not far away, we will pass the peak of produced volume and production decline will start. In this environment it is important for everyone to do their best to reduce negative environmental impact and develop products and systems that are more efficient and environmentally friendly. Depro have over many years implemented measurements and actions to be in front of this and we have target to be zero emissions by 2030 and help our customers to do the same.

OGI: So how do Depro meet this change in the oil and gas market?

Olsen: Depro has invested in technology and people to be better prepared to meet the market needs for zero emission suppliers. In parallel with this initiative we are leading the company step by step into the Industry 4.0. Both those initiatives require a new mindset on how we operate, how we serve our customers and how people and machines interact to each other. We think the most important factors to be successful in this new environment is to have a business culture that embrace and motivate our employees to use new technology to reduce waste (meaning reduced man-hours, execution-time and material), and our ability to direct our initiatives into customer value.

Olsen continues: At the same time, we believe that human interface in subsea operations will be the preferred solution many years ahead, but new technology can help to perform the operation quicker and safer, even with less experienced personnel. Depro are well prepared to take a front runner position in the subsea market for remote operated tooling. One example of this is the BLUEROC concept which was introduced to the market this year.

OGI: Would you give us a brief description of BLUEROC?

Olsen: BLUEROC is a mobile 20-foot container with a complete ROV system that is quick to mobilize and can be used on many different vessels. It contains everything needed to launch and operate the ROV (Control Room, Winch, LARS, TMS), just connect power, and you are ready to go.

Olsen continues: This product is part of Depro’s long-term strategy where we want to offer new innovative concepts that can be easily controlled remotely from land and provide high value creation for our customers. We have discussed our ideas with some customers and the response is extremely positive.

OGI: What is the biggest advantage of the new solution?

Olsen: It is the small footprint required and all parts to operate the system are assembled and connected, ready for operation. Just load the system on a ship and start the operation without any further preparation.

The system is perfect for visual inspection, 2D and 3D scanning, and also have the opportunity to add small tooling for spot cleaning, NDT inspection, and a small manipulator arm.

The use of modern technology and control systems provides great opportunities and cost savings for customers. The system is prepared for remote control from the control room on the vessel or from shore. Since the control system is built with semi-automatic processes, the system is less sensitive to delays that could exist in the communication network.

OGI: You told us that this BLUEROC system was a cost-efficient solution, where are those savings?

Olsen: The biggest cost savings aside from the price to buy or rent the BLUEROC system, are connected to use of smaller vessels with lower day-rates, and less expensive personnel cost. The saving in personnel cost is connected to installation costs and operational costs. If we compare BLUEROC with traditional ways to install and operate the system you would need fewer people and perform the job much quicker. BLUEROC is built to be operated by standard offshore personnel with a one-week training course. One customer stated that they got more than 75% savings from the current way of performing inspections, and the investment costs were fully covered with the savings in the first campaign. Depro has big plans for the ROV solution, and a further development of the concept is already started.

OGI: Do you have any ending remarks?

Olsen: Right now, we are in a phase where we are building up a new group within our company to strengthen the operational support and we are in need for more personnel. I would recommend to have a look at our homepage, www.depro.no that way you can get more details around us as a company and what we deliver.