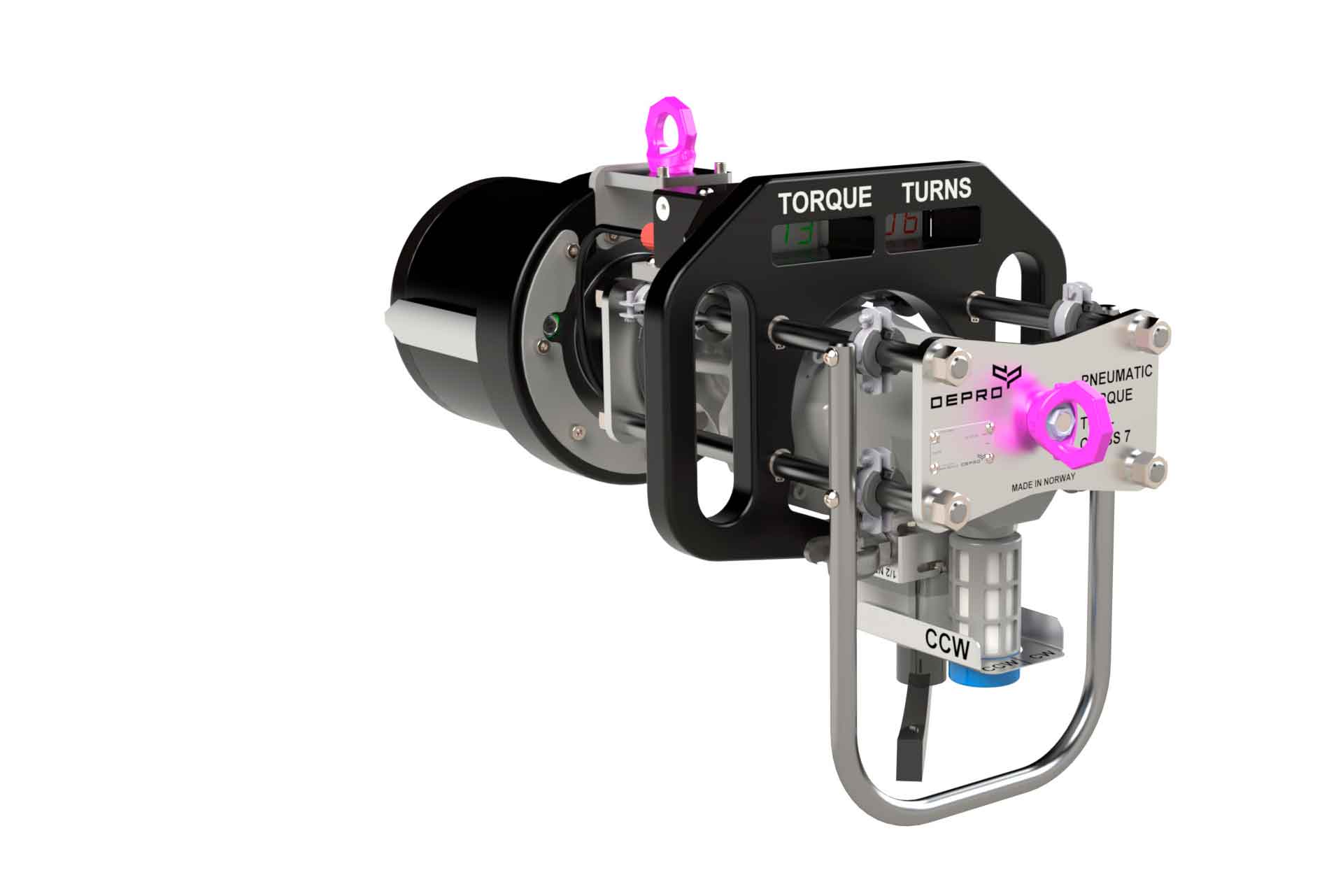

Torque Tool pneumatic powered, perfect for SIT and topside use

Referenced standards: API 17H/17D, ISO 13628-8

Description:

The pneumatic Torque Tool (pTT) is designed to be operated as a stand alone tool. It has a multi interface setup in order to meet all referenced standards.

Base unit is set up with interface (nose):

– API 17 H (short)/API 17 D 1st edition.

The pTT display give full control on torque and turns, allowing the operator to set correct

torque and turns to avoid overload of the object in operation.

Torque accuracy 5% through the scale.

The tool can be operated through the customized Depro Pneumatic Control Unit (PCU). Torque tool is calibrated at delivery.

Spesifications:

Standard torque range: 8 – 40 kNm, Max pneumatic flow pressure 7 bar, air consumption 60 ls max. turn speed (under load) 1,0 RPM, weight 100 kg

Dimensions, 3D-model available on request

Base unit:

– pTorque Tool Class 7 DEP-GA-0898

– Depro Pneumatic Control Unit DEP-GA-0930

Available adapters and addons:

– Class 7 (Long) adapter, API 17H, ISO 13628-8 DEP-GA-0518

– Class 7 (Short) adapter, API 17H 3. edition DEP-GA-0892

– Class 6+ adapter, ISO 13628-8 DEP-GA-0799

– Class 6 adapter, API 17H, ISO 13628-8 DEP-GA-0519

– Class 5 adapter, API 17H, ISO 13628-8 DEP-GA-0496

– Customized adapter VCS/GHO/OCS DEP-GA-0520

Dimensions, 3D-model available on request

Customized torque range on request.

Tool adapters, verification units, control systems etc. see specific datasheets.

Download Product Sheet: