Rental solutions

Many customers see a rental solution to be more attractive than buying a product. Depro provide this service, and most of our products can be rented.

Benefits of rental solutions:

- Reduced CAPEX

- Hassle-free tool management and reduced storage space

- Depro AS, the manufacturer, secure correct maintanance, quality and life cycle management

- Reduced risk of failure during the operation of older tools.

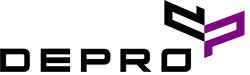

Lockout Tool (LOT)

Function of the LOT is to hold a valve in a locked position. This function is manually enabled by the ROV operator. The LOT stroke length (to locked position) is fixed and should be specified by the customer, along with the interface type.

Linear Actuator Override Tool (LOAT)

Linear Actuator Concept is designed to save costs and achieve increased interface flexibility. The main components are Hydraulic Power Module, Interface Units and Lockout Unit.

Hot Stab System

Hot-Stabs used to power hydraulic tools, transfer fluid, perform chemical injections, and to monitor pressure. Designed for use subsea, and operated with ROV.

Heavy Duty Flying Lead Orientation Tool

The Heavy Duty – Flying Lead Orientation Tool (FLOT) is designed to be used to guide, orientate, and connect flying leads subsea. HD-FLOT tool is primarily designed to take the Depro Class 2-4 Torque Tool (TT) but interface to other Torque Tools is available on request.

Blueroc EDM Cutting Tool with Utility Skid

A high accuracy cutting tool for subsea operations. The cutting tool is optimized to perform cutting on subsea clamps drive screw in any material. The EDM tool has the possibility to be set up and perform high precision cutting on any other structure.

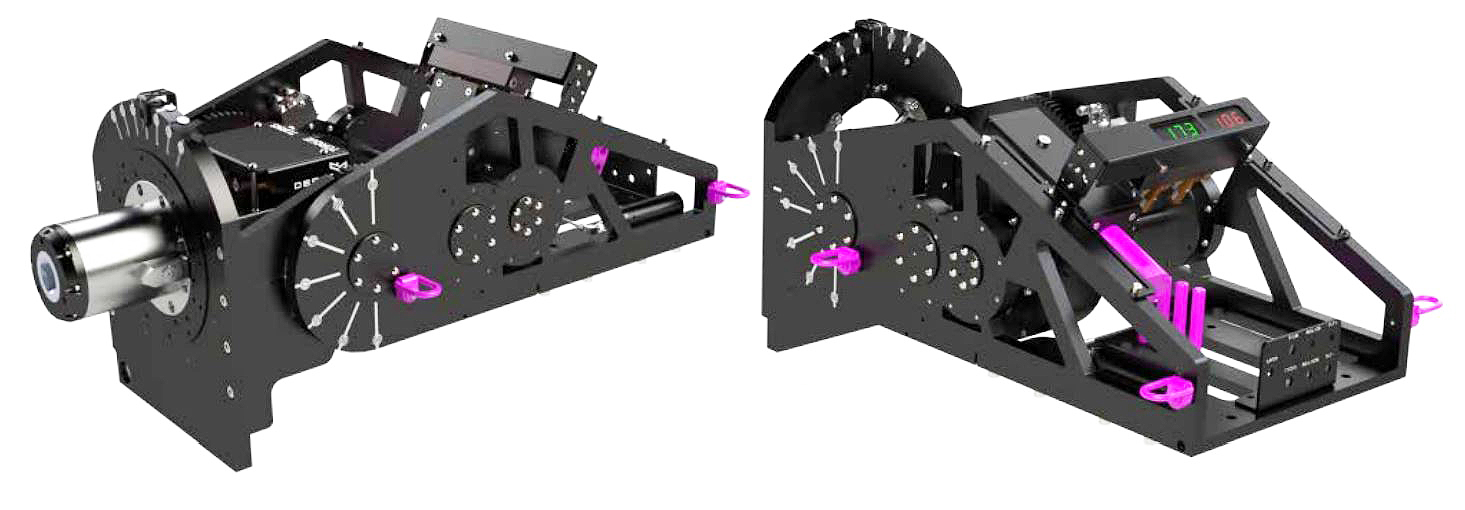

Compact buddy ROV skid for a work class ROV system

The system gives the ROV operator the opportunity to access confined spaces, and a view from a different angle than the bigger work class ROV system can perform. This gives the ROV operator much better visual control with the operations.

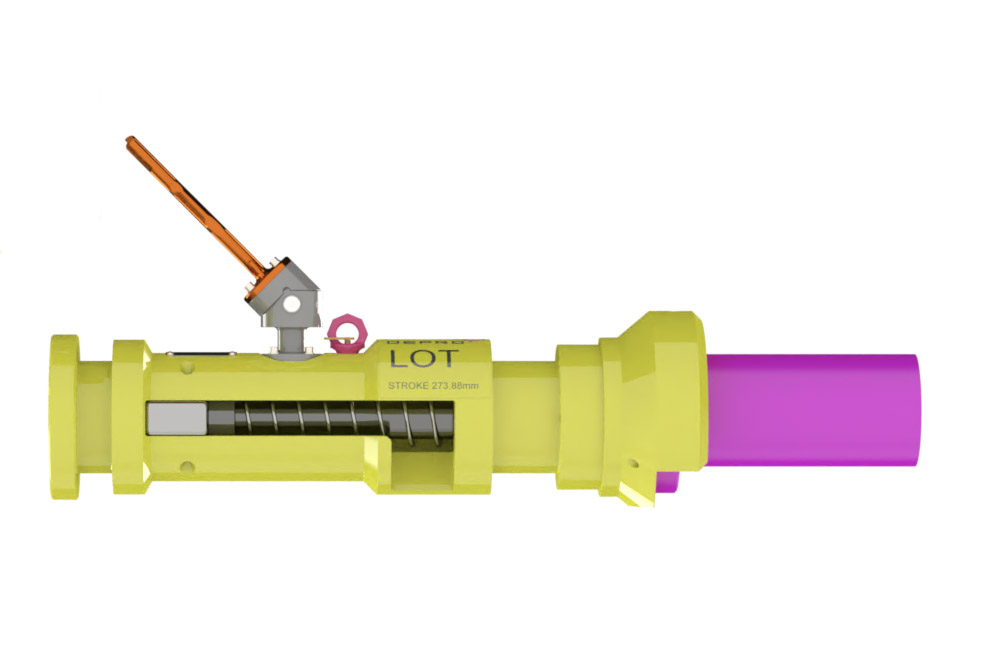

Torque Tool Class 1-2, API 17H & ISO13628

Standard torque range is 67-271 Nm, Max turn speed 50 RPM. The display shows torque and turnes. Designed for 3000m water depth. Delivers in a transportation box.

Torque Tool Class 2-4, API 17H & ISO13628

Torque range is 271-2711 Nm, Max turn speed 14 RPM. The display shows torque and turnes. Designed for 3000m water depth. Delivers in a transportation box.

Torque Tool Class 5, API 17H & ISO13628

Torque range is 1000-6779 Nm, Max turn speed 5 RPM. The display shows torque and turnes. Designed for 3000m water depth. Delivers in a transportation box.

Torque Tool Cl. 6-7, API 17H/17D & ISO13628

Torque range is 8-40 kNm, Max turn speed 3 RPM. The display shows torque and turnes. Designed for 3000m water depth. Delivers in a transportation box.

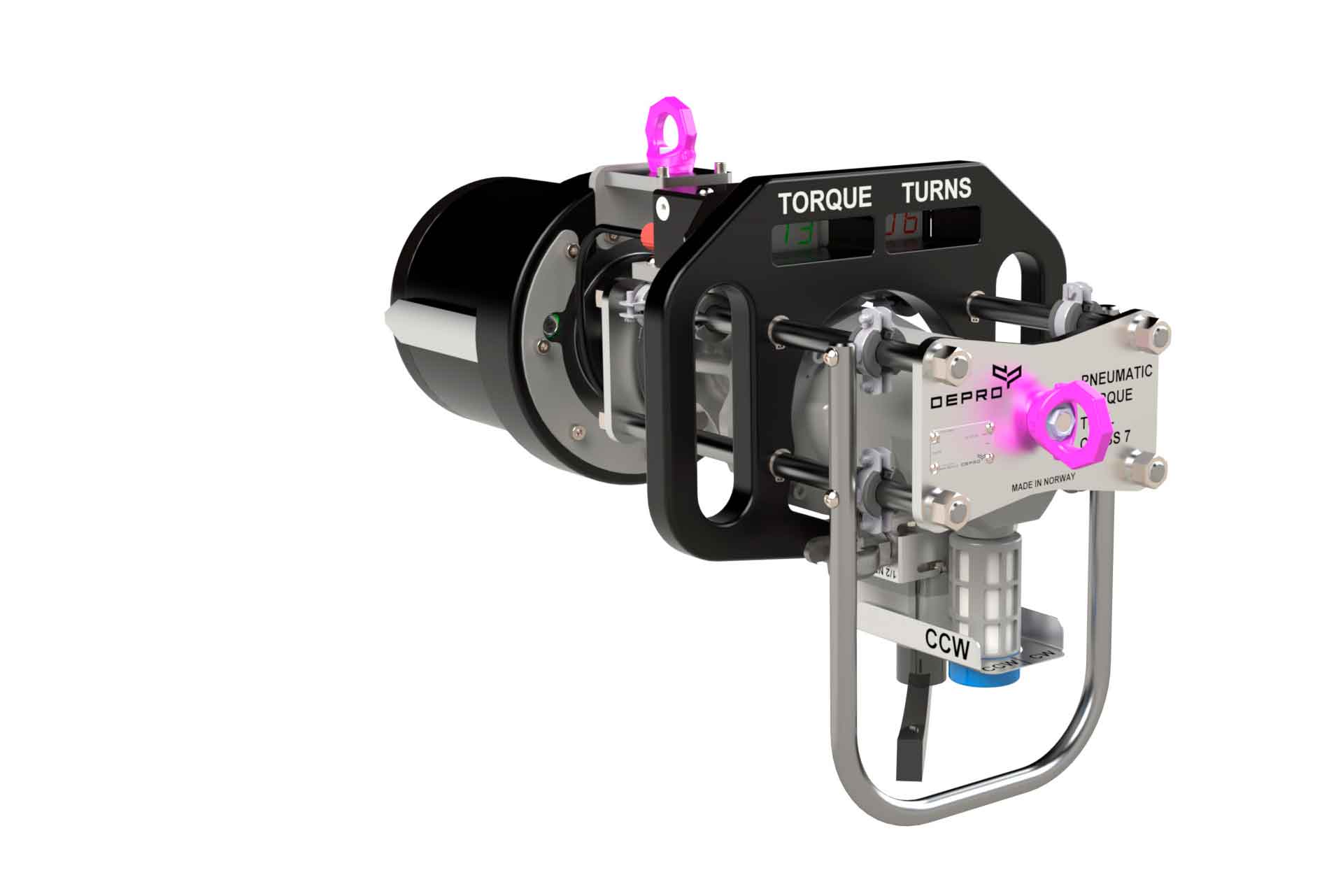

Pneumatic Torque Tool Cl. 5, API 17 H (short)/API 17 D 1st edition

The pneumatic Torque Tool (pTT) is designed to be operated as a standalone tool. It has a multi-interface setup to meet all referenced standards.

Base unit is set up with interface (nose): – API 17 H (short)/API 17 D 1st edition.

Tool Control Unit-TCU

By connecting the tool to a seperate control unit, you get better documentation on tool performance and specified data related to torque and turnes during operation. The data output is valuable to define item integrity issues and that way easier to perform planned maintanance during lifetime.

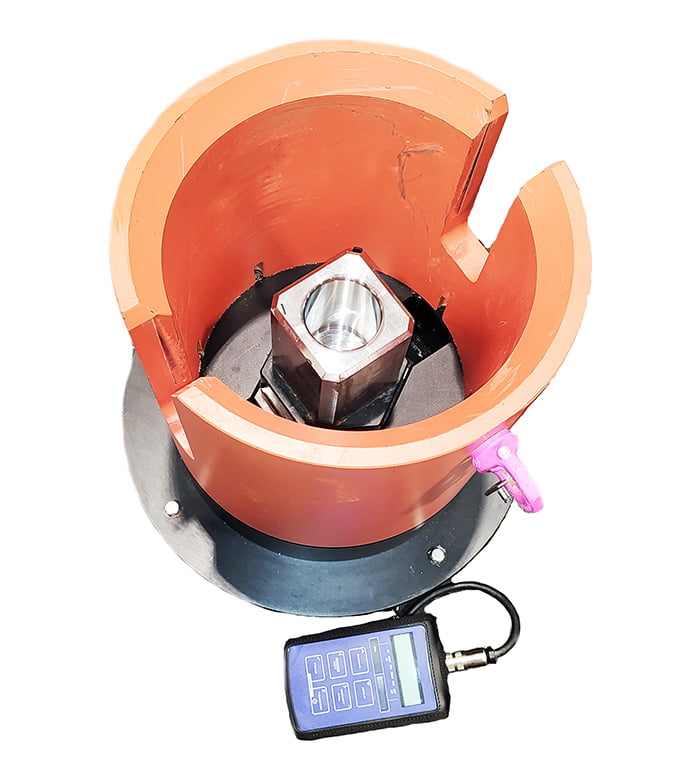

Verification unit for Torque Tools Class 4

Verification unit for Torque Tools. The unit is made to verify correct torque before performing subsea operations.

Verification unit for Torque Tools Class 5

Verification unit for Torque Tools. The unit is made to verify correct torque before performing subsea operations.

Verification unit for Torque Tools Class 7

Verification unit for Torque Tools. The unit is made to verify correct torque before performing subsea operations.

HPU 300bar 35l/m – DNVGL-ST-E273

5 independent lines, 160l oil reservoir, electrical motor 400V 3 phase, 50Hz, 18,5kW

HPU 300bar 30l/m – DNVGL-ST-E273

OCEANIC version – The HPU is designed to use Oceanic fluid, 5 independent lines, 160l oil reservoir, electrical motor 400V 3 phase, 50Hz, 18,5kW

HPU 207bar 50l/m – DNVGL-ST-E273

OCEANIC version – The HPU is designed to use Oceanic fluid. 5 independent lines, 160l oil reservoir. Electrical motor 18,5Kw, electrical input 3 phase 400/440/690V 50/60Hz, electrical consumption 33,5/33,5/19,4A.

Workshop container 10 ft

Standard 10 ft offshorecontainer, for tooling storage and tooling maintanance. The tooling inventory can be customized.

Delivered in a foamed aluminium box

Contact us for more information:

Jan Arild Herredsvela

CSO

Department Manager Sales

Tel.: +47 950 41 332 / +47 51 48 21 90

Mail: sales@depro.no

Arild Vinningland

KAM

Key Account Manager

Tel.: +47 909 18 866 / +47 51 48 21 90

Mail: sales@depro.no